Pharmaceutical & Medical

Our innovative coffee packaging solutions ensure your brand stands out while preserving the freshness and flavor of your coffee.

We are committed to advancing coffee packaging standards, offering modern, efficient solutions that support sustainability and maintain your coffee’s quality. With over 10 years of collective experience, we are trusted for our reliability, exceptional customer service, and high-quality products. Our packaging solutions ensure: Modified Atmosphere Packaging (MAP) options to preserve your coffee’s unique aroma, acidity, body, and flavor. Efficient designs that enhance your brand, attract attention, and offer superior functionality for packing, storing, and displaying. Strength and durability to protect your product during transport and storage. Sustainability, reducing your environmental impact and appealing to eco-conscious consumers. Whether you hand-fill coffee bags or use automated equipment, we provide a wide range of customizable pouch styles, sizes, and eco-friendly packaging materials. We can manage large orders with ease and also respond quickly to smaller, short-run requests. Understanding the importance of visual appeal, our printing services deliver top-quality coffee packaging that shines on the shelf!

Custom printed flexible packaging is the gold standard for tea and coffee brands.

Inquire with Sante to learn more about our stand-up pouches.

| MOQ | 100pcs by digital print, 10000pcs by gravure print. |

|---|---|

| Size | 1oz, 2oz, 4oz, 8oz, 12oz, 16oz, 24oz,32oz, 1lb, 2lbs, 3lbs, 4lbs, 5lbs |

| Material | PET+AL/PETAL/Kraft Paper+LLDPE |

| Thickness | 70Mircons-200Mircons (2.5Mil-8Mil) |

| Function | Punch Hole, Handle, Ziplock, Valve, Window |

| Printing | D-Met Printing, Metallize, Vanishing, Matte Finishing |

| PRODUCT | SIZE | THICKNESS | MATERIAL | MOQ | BARRIER LEVEL |

| STAND UP POUCH | 60x110cm (min), 320x450cm (max) | 60 microns – 180 microns (2.5mil – 7.5mil ) | BOPP/PET + PETAL + LLDPE + CPP | 100 pieces | Low / Medium |

| FLAT BOTTOM POUCH | 80x120cm (min) 320x450cm + 120cm (max) | 60 microns – 180 microns (2.5mil – 7.5mil ) | BOPP/PET/PA + Kraft Paper + AL FOIL + PETAL + LLDPE + CPP | 100 pieces ( Depend on size ) | Medium / High |

At Sante Packaging, our coffee bags feature advanced degassing valve technology that allows air to escape while preventing outside air from entering. This technology effectively keeps coffee fresh and tightly sealed within the pouch.

The degassing valve enables the release of built-up carbon dioxide, while moisture, oxygen, and light—known coffee freshness killers—are kept out. This one-way degassing valve ensures that customers receive fresh coffee.

Traditional coffee packaging has been transformed by our coffee bags, offering superior packaging solutions. When selecting a coffee packaging product, several key factors should be considered, which we will discuss further.

One critical factor is maintaining the coffee's freshness until it reaches the customer. Suppliers must ensure that coffee stays fresh during distribution to businesses, stores, and cafes, or when shipped internationally. Freshly roasted coffee releases carbon dioxide, making it challenging to maintain its freshness.

To preserve freshness, we utilize Modified Atmosphere Packaging (MAP) options. Send us your inquiry to create your perfect coffee bags.

Premier Stand up Pouches Supplier

Flat Bottom Coffee Bags

The flat bottom pouch, also known as a box pouch, is a top choice in coffee packaging, offering both functionality and a stylish look. Its flat bottom design allows it to stand upright easily, which is ideal for shelf display and maintaining product freshness.

What sets this pouch apart is its versatility. You can choose between a tall, slim design or a more compact, square shape to suit your brand’s needs. The large front surface provides ample space for eye-catching branding, ensuring your product stands out on the shelf.

Additionally, the side gussets can be printed separately, allowing for more creative customization. This makes the flat bottom pouch a great option for brands looking to balance aesthetic appeal with practical packaging.

Stand Up Pouch

Stand up pouches stand out as a modern and premium alternative to traditional tea and coffee packaging, offering consumers a sense of artisanal quality and attention to detail. The upright design not only enhances shelf presence but also gives the product a refined, high-end look. Paired with a resealable zipper, this packaging solution is perfect for maintaining freshness while providing an easy, user-friendly experience. Brands that prioritize both convenience and visual appeal will find the stand up pouch an ideal option, as it combines functionality with style, offering customers a practical and reusable packaging choice. Whether for retail or specialty markets, stand up pouches help reinforce the perception of quality and craftsmanship, making a lasting impression on consumers.

Printed Film

Sante Packaging offers a wide range of high-quality printed films, available in quantities starting from as low as 10,000 impressions. These films are designed for use on high-speed form-fill-seal machines, compatible with both vertical and horizontal orientations. Sante’s printed films are versatile and can be used to create various packaging formats, such as sachets, pillow packs, and more. Our printed film solutions ensure durability, excellent print quality, and efficiency, making them ideal for brands looking to enhance their packaging with eye-catching designs and seamless production processes.

What we provide

This is How Our Service Start

Initial Consultation

Step 1

Design Review

Step 2

Price Estimate

Step 3

Sample Confirmation

Step 4

Production and Delivery

Step 5

Post-Sales Service and Repeat Orders

Step 6

FAQ

Exclusive Flexible Packaging for Your Brand

A coffee bag will feature valves/vents around parts of its body.

Valves/Vents are one-way units that allow carbon dioxide to escape.

The coffee product will exert carbon dioxide for about 24 hours after roasting.

The valves/vents will ensure that carbon dioxide will move out while providing any extra oxygen inside the bag will be removed.

If you prefer, you can email us with your detailed request, and we will contact you, normally within 4 working hours.

As it is produced, a valve will be added to the coffee bag layout.

The design ensures the valve is placed well to allow air to leave the bag.

Coffee bags can come in various sizes.

A one-ounce coffee bag is small enough for individual servings.

You can also get something that weighs three to five pounds/2-5 Kg for bulk purposes. We also offer some bulk options in 10Kgs.

A single serving of coffee requires about 10 grams of grounds, which is about a third of an ounce.

A one-ounce coffee bag is the closest you could get to a single serving.

All coffee bags are ready for multiple cups of coffee.

It should be easy for the customer to close and open the coffee bag for later use.

You can order a coffee bag made with one of many biodegradable items.

Among these biodegradable compounds include kraft paper, and PLA, and maybe we can use a 100% recyclable PE pouch.

Such items could be added to a compost pile alongside the used coffee grounds one produces.

A plastic band can be used on the inside part of a coffee bag.

The plastic material helps you to seal up the bag when not in use.

The seal ensures the coffee contents will stay intact and not spoil over time.

The laminated film adds an extra barrier on the inside to prevent oxygen from entering the bag.

The film will go on the inside lining of the bag for added protection.

You can open a sealed coffee bag by tearing off the top part and opening the zipper.

The zipper can be closed to seal off the bag.

A plastic band that secures the bag in its place may also be used if you prefer.

Not All Coffee Companies Will Sell Coffee Bag Products. What Standards Might These Groups Have Surrounding How Well These Coffee Products Are Made?

The degassing valve ensures that oxygen will not come into the coffee bag while carbon dioxide is released.

The one-way design ensures that the excess gas is removed and that the coffee will taste well.

Including the roast date on the coffee bag is essential.

This date provides information on when the coffee was initially roasted and ready for consumption.

It helps determine the timeframe before the coffee reaches its expiration.

Consumers often rely on the roast date to identify the freshest coffee available.

Coffee is typically more attractive to customers if it falls within five to ten days of being roasted.

A quad seal bag includes side gussets.

These gussets increase the bag's capacity.

This design allows the bag to expand easily, accommodating more coffee grounds.

The shelf life of coffee depends on its form and whether the bag is sealed or opened.

Ground coffee remains fresh for about three to five months after the roast date.

Whole bean coffee can last between six to nine months.

Once opened, the freshness reduces significantly.

Ground coffee typically lasts up to three months after opening.

Whole bean coffee retains its quality for about six months after the initial use.

To extend the coffee’s lifespan, proper storage and ensuring the bag is tightly sealed are essential.

Storing a coffee bag in the freezer can significantly extend its shelf life.

Ground coffee can remain fresh for up to a year in the freezer.

Whole bean coffee can last as long as three years when frozen.

However, once the bag is opened, the lifespan of both ground and whole bean coffee is reduced by half.

Expert Staff and Tailored Packaging Solutions

Our professionally trained staff excel at all levels, equipped with the skills to produce top-quality products and deliver exceptional service. Our in-house packaging specialists are ready to discuss your requirements and provide expert advice on the best packaging solutions for a wide range of industries.

Stay ahead of packaging trends with our custom printed pouches designed to meet evolving consumer functionality demands.

Unlock endless possibilities for creating special editions, launching new products, and making an impact at exhibitions and events with our fast and flexible service.

We enhance the value of your packaging project through collaboration and print file optimization, leveraging the expertise of our professional graphics team.

Blog :

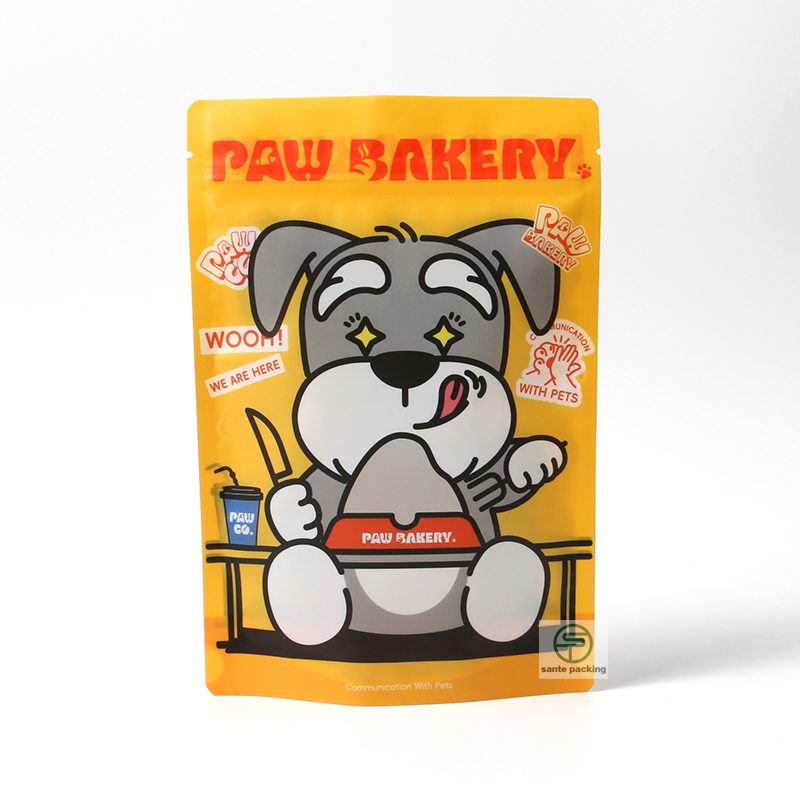

Types of Pet Food and Pet Snack Bags

There are several types of bags suited for different kinds of pet food and snacks. Let’s take a closer look:

Stand-Up Pouches

These are a staple in packaging across industries, and pet food is no exception. Stand-up pouches are widely recognized as the go-to option for packaging pet food. They offer excellent shelf visibility and are easy to pack, making them a favorite among pet food brands. Available in a variety of colors and sizes, these pouches can be tailored to fit your specific pet’s needs.

Stand-up pouches come in three main designs:

- Clear front windows

- Fully transparent

- Shaped pouches with different levels of barrier protection, from low to high.

Many pet owners have praised these pouches for their convenience, confirming they meet all their pet food storage needs.

Gusset Bags

A strong competitor to stand-up pouches, gusset bags share many of the same qualities. Initially used for human food products like bread and biscuits, these bags have since found their place in the pet food industry.

Having been around for more than half a century, gusset bags are well-loved for their portability and are often made from Kraft paper, providing robust protection for pet food. Their durability and ease of use make them a popular choice for pet food packaging.

Quad Seal Bags/Flat Bottom Pouches

These flexible bags are perfect for pet food, especially when larger capacities are needed. Quad seal bags are reinforced with tight seals on all four corners, giving them a sturdy, box-like base that provides excellent stability and prevents spills. With a larger top-opening, these pouches offer plenty of space for easy filling and dispensing, making them extremely convenient for both packaging and feeding.

Shaped Pouches

Shaped pouches bring a unique and fun twist to pet food packaging. They can be customized into any shape, adding a playful element that can even reflect your pet’s personality. These pouches are not only visually appealing but also reusable, allowing for refills and long-term use, making them a sustainable and cost-effective option.

With their creative designs and the ability to represent what’s inside the pouch, shaped pouches help your product stand out on the shelf.

Kraft Paper Pouches

Kraft paper pouches offer a natural and eco-friendly solution for pet food packaging. Available in different sizes based on customer demand, these pouches provide an organic look and feel, with colors that may vary slightly due to the nature of the Kraft paper. While they may discolor with extended exposure to sunlight, their natural appeal and custom printing options make them increasingly popular in the pet food packaging market. Expect their demand to rise as sustainability becomes more of a priority for brands and consumers alike.

Types of Coffee Bags

Coffee is a delicate product that requires proper packaging to preserve its freshness and quality. Any mistake in the packaging process can lead to a shortened shelf life, loss of aroma, and diminished taste—all of which negatively affect the coffee’s overall value.

As a coffee roaster or producer, it’s essential to prioritize high-quality coffee bags. Premium packaging not only enhances the appeal of your product but also attracts retailers from supermarkets, malls, and small-scale shops. These retailers value coffee packaging that extends shelf life, preventing losses and ultimately boosting sales and profits.

At Sante Packaging, we understand the intricacies of the coffee market. We specialize in producing coffee bags in a variety of styles, shapes, materials, and colors—tailored to meet market demands. Our coffee bags are crafted using laminated material films that offer strong barriers against oxygen, moisture, odors, water vapor, and contamination, ensuring your coffee retains its aroma and flavor for an extended period.

In addition, our coffee bags come equipped with practical add-ons, such as resealable zippers, degassing valves, and easy-pour spouts for added convenience. We are also committed to customization, allowing you to collaborate with us on creating the perfect packaging that matches your brand’s identity in any shape, size, or color.

At Sante Packaging, we categorize our coffee bags into the following main types:

- Stand-up Coffee Bags

- Flat Coffee Bags

- Side Gusseted Coffee Bags

- Block Bottom Coffee Bags

- Spout Coffee Bags

Explore the specifications and details of each category to find the perfect solution for your coffee packaging needs.

The Benefits of 3-Side Seal Pouches by Sante Packaging

At Sante Packaging, we take pride in providing innovative packaging solutions that cater to a variety of industries, and our 3-side seal pouches are no exception. These pouches have significantly transformed the packaging industry by offering numerous advantages that enhance both product preservation and user convenience.

One of the most notable features of 3-side seal pouches is their incredible versatility. They can be utilized for packaging a wide range of products, from food items to cosmetics, pharmaceuticals, and even pet supplies. This adaptability makes them a go-to choice for businesses looking for a reliable packaging option that can meet diverse needs across different sectors.

Unlike rigid packaging solutions, 3-side seal pouches are remarkably lightweight, which contributes to a key benefit—reduced shipping costs. The pouches themselves add minimal weight to the packaged goods, ensuring that the overall product weight remains low. This reduction in weight can lead to substantial savings in transportation and logistics, making them a cost-effective option for companies engaged in large-scale distribution.

Customization is another area where 3-side seal pouches excel. At Sante Packaging, we offer the ability to tailor these pouches to your specific requirements, whether it’s the size, color, shape, or design. The flexibility in design allows businesses to create packaging that not only fits their product perfectly but also aligns with their branding and marketing needs. Whether you require vibrant colors or unique patterns, 3-side seal pouches offer the creative freedom to craft packaging that stands out on store shelves.

In addition to their design flexibility, 3-side seal pouches are crafted from high-quality materials that provide excellent barriers against environmental factors such as moisture, air, and light. This makes them ideal for preserving the freshness of food products, as the inner aluminum lining creates a protective layer that significantly extends the shelf life of perishable goods. For temperature-sensitive products, these pouches also demonstrate superior heat tolerance, allowing them to be safely heat-sealed without compromising the integrity of the packaging.

Another major advantage is the cost-effectiveness of 3-side seal pouches. Made from readily available materials, they are inexpensive to produce, which makes them a budget-friendly option for businesses of all sizes. This affordability does not come at the expense of quality—despite their low production cost, these pouches maintain high standards of durability and product protection.

User convenience is also at the forefront of the design of our 3-side seal pouches. They are equipped with various closure options, making it easy for consumers to access the product without hassle. Whether it’s a tear-notch, zipper, or resealable closure, these options enhance the overall user experience by ensuring that products are easy to open, dispense, and store.

One of the most critical aspects of any packaging solution is product safety, and 3-side seal pouches meet this criterion with flying colors. The materials used are stable and non-reactive, ensuring that they do not compromise the quality or safety of the packaged goods. This is particularly important for products intended for human consumption, as these pouches have been rigorously tested to meet stringent safety standards.

In summary, Sante Packaging’s 3-side seal pouches are an exceptional choice for businesses looking for versatile, customizable, and cost-effective packaging solutions. They offer excellent product protection, maintain freshness for extended periods, and are both user- and environmentally friendly. As a leading provider of high-quality packaging products, Sante Packaging is committed to helping our clients enhance their product presentation and delivery with packaging solutions that are as reliable as they are innovative.

SantePack Stand-Up Pouch Manufacturing Process Guide

A stand-up pouch is a versatile and flexible packaging solution designed to stand upright on its bottom, making it ideal for product display, storage, and easy usage. This comprehensive guide will walk you through the entire SantePack stand-up pouch manufacturing process, covering every essential stage from initial planning to final quality testing.

1. Determine the Purpose of the Stand-Up Pouch

- The first and foremost step in manufacturing a stand-up pouch is to clearly define its specific purpose. Whether the pouch is intended for preserving freshness, protecting the product, or simply storing it, understanding its purpose is critical.

- Once the purpose is determined, it becomes easier to choose the appropriate materials, design, size, and shape that will best meet the needs of the product it will contain.

- For instance, if the pouch is to be used for packaging food or beverages, selecting materials that ensure the safety and freshness of the contents is crucial. This step helps in laying the foundation for all subsequent decisions in the manufacturing process.

2. Design Process

- After establishing the purpose of the stand-up pouch, the next step is to engage in the design process. This involves using specialized design software to create a conceptual model of the pouch.

- The design phase is complex and requires a deep understanding of how to use the software to produce a design that meets both functional and aesthetic needs.

- During this stage, several factors need to be considered, including the type of content, the target market, and the overall functionality of the pouch. For example, you might need to decide whether to include features like ziplocks, spouts, press-to-close seals, or tear notches, depending on the content the pouch will hold.

- Additionally, the design should take into account customer preferences and market trends, ensuring that the pouch not only serves its functional purpose but also appeals to the consumer. Customizing the design to suit specific customer requirements can also help differentiate your product in a competitive market.

- Another important aspect of the design process is estimating the overall cost and potential return on investment. By considering these factors early on, you can make informed decisions that balance quality with cost-effectiveness.

3. Selecting the Right Material

- The choice of material is a critical component in the manufacturing of stand-up pouches, as it directly affects the practicality, durability, and efficiency of the final product.

- Typically, a stand-up pouch consists of three layers: the inner layer, the middle layer, and the outer layer, each serving a specific purpose. These layers are laminated together to form a cohesive and functional pouch.

- Inner Layer: The inner layer is in direct contact with the product and is often made from materials like linear low-density polyethylene (LLDPE). This material is FDA-approved for food contact, provides excellent heat-sealing properties, and ensures the product is tamper-proof, thereby extending shelf life and boosting consumer confidence.

- Middle Layer: The middle layer varies depending on the product’s requirements. Common materials include metalized film, aluminum foil, and polyethylene terephthalate (PET). Each material offers unique benefits, such as durability, barrier protection, and strength. For example, aluminum foil is ideal for products requiring a longer shelf life, while metalized film is suitable for products with a faster turnover.

- Outer Layer: The outer layer is the visible part of the pouch and plays a significant role in brand messaging and consumer attraction. Kraft paper is often used for its natural, eco-friendly appeal, enhancing the aesthetic and environmental value of the pouch. This layer also provides durability, strength, and protection against external elements.

4. Choosing the Suitable Design

- Selecting the appropriate design for a stand-up pouch is closely linked to the type of product it will contain and the preferences of the target market.

- The design should be functional, easy to use, and visually appealing to stand out on crowded retail shelves. For instance, if the product is a liquid or semi-liquid, a pouch with a spout or cap would be more practical, allowing consumers to easily pour and reseal the contents.

- Customization is key in this stage. The pouch should be tailored to meet the specific needs of your target customers, whether it involves unique shapes, sizes, or additional features like euro slots for hanging displays. A well-designed stand-up pouch not only protects the product but also enhances the consumer’s experience by making the product easy to access, use, and store.

- Additionally, incorporating resealable features like ziplocks or press-to-close seals ensures that the product remains fresh even after opening, adding to the pouch’s functionality and consumer appeal.

5. Manufacturing the Stand-Up Pouch

- The manufacturing process of a stand-up pouch involves several intricate steps. It starts with the raw materials being passed through sets of plows that shape the material into W-shaped gussets, which are crucial for the pouch to stand upright.

- If the pouch requires a zipper, it is sealed onto the inner surfaces of the material near the top edge early in the process. Other access methods, such as perforations, spouts, or tear notches, are also added at this stage, depending on the design.

- Vertical seals are then created along the sides of the pouch, and the bottom folds are cut and sealed to form the main container part of the pouch. The final shape of the pouch is achieved by cutting it apart vertically through the center of the side seals.

- Once the pouch is formed, it is filled with the product, after which the top seal is applied, and the ziplock is closed. A notch is typically added near the top to facilitate easy opening by the consumer.

6. Quality Testing

- Ensuring that each stand-up pouch meets the required quality standards is vital. This is achieved through a series of rigorous tests designed to assess the pouch’s durability, functionality, and safety.

- Tensile Test: This test evaluates the material’s strength and how much it can stretch before breaking.

- Drop Test: This test determines the height from which the pouch can be dropped without sustaining damage, ensuring it can withstand handling during shipping and storage.

- Burst Test: This measures the maximum pressure the pouch can endure before bursting, which is crucial for products that may expand under certain conditions.

- Seal Strength Test: This assesses how well the seals hold up over time, ensuring that the contents remain secure and uncontaminated.

- Vacuum Test: This test checks for any potential leaks when the pouch is subjected to vacuum pressure, ensuring the integrity of the packaging.

- Bypassing these tests, the stand-up pouches demonstrate their reliability and suitability for a wide range of products, guaranteeing that they meet the highest standards of safety and quality.

In conclusion, the SantePack stand-up pouch manufacturing process is a meticulously planned and executed operation that ensures each pouch is crafted to perfection. From determining the purpose of the pouch to selecting the right materials and design, and finally ensuring that the product meets all quality standards, every step is designed to produce a pouch that not only meets but exceeds consumer expectations.

Stand Up Pouch Manufacturing Process – A Complete Guide

A stand-up pouch is a versatile packaging solution designed to stand upright, providing optimal display, storage, and usage efficiency.

This guide will cover all essential details of the stand-up pouch manufacturing process.

Step 1: Define the Purpose of the Stand-Up Pouch

The first step is to identify the specific purpose of the stand-up pouch—whether it’s for preserving, protecting, or storing products. Understanding the intended use is crucial for selecting the appropriate materials and design.

Step 2: Designing the Stand-Up Pouch

Once the purpose is clear, the next step is to create a conceptual design using design software. This process involves determining factors like capacity, shape, and any special features such as zippers or spouts, based on the product’s needs and market expectations.

Step 3: Choosing the Right Material

The material used plays a critical role in the pouch’s functionality. Options include aluminum foil for moisture and oxygen barriers, or polymers for mechanical strength and heat-seal capabilities. A typical stand-up pouch has three layers—inner, middle, and outer—each made from different materials to ensure durability and protection.

Step 4: Selecting the Appropriate Design

The design of the pouch depends on the product it will contain. Liquid products may require a spout, while dry goods might need a ziplock. Customizing customer preferences and market demands is vital for enhancing product visibility and usability.

Step 5: Manufacturing the Stand-Up Pouch

The manufacturing process involves creating a W-shaped gusset, adding any required closures like zippers, and sealing the pouch’s sides. The pouch is then filled with the product, sealed, and cut to the desired shape.

Step 6: Quality Testing

Finally, the pouches undergo rigorous quality testing, including tensile, drop, burst, and puncture resistance tests, to meet industry standards.

For more information or inquiries about our stand-up pouches, feel free to contact us

Send Us a Message

Why Choose Us

- High Quality

We use advanced technology and strict quality control to ensure top-notch packaging solutions.

- Cost Savings

Save 30%-40% by buying directly from our factory.

- Customization

Tailor-made packaging to meet your specific needs and preferences.

- Experience

With years of expertise, we deliver reliable and innovative packaging solutions.

- Experience

With years of expertise, we deliver reliable and innovative packaging solutions.

Get A Quote Today

Get a quote today to find the best packaging solutions for your needs. Our team is ready to provide competitive pricing and detailed information to help you make an informed decision.